Ductless mini split older homes retrofit without ductwork

Thinking about air conditioning or heat for an older house without ductwork can feel like a major project. A ductless mini split system offers efficient comfort without tearing into walls for new ducts. This guide explains when a mini split retrofit without ductwork makes the most sense, how to size it, where to place the equipment, what to expect for electrical and structural needs, typical costs, and how to keep it running clean. It draws on guidance from the U S Department of Energy and ENERGY STAR so you can make smart choices with confidence. For homeowners comparing options for additions, single rooms, whole home retrofits, or persistent hot and cold spots, this is a practical roadmap that puts comfort, efficiency, and historic character first.

Why mini splits suit older homes

Many homes built before central air relied on radiators, baseboards, or gravity ducts. Running new sheet metal through finished walls and ceilings can be expensive and disruptive. A ductless mini split pairs a quiet outdoor unit with one or more compact indoor heads. Refrigerant lines, a control cable, and a small condensate drain connect the two through a neat wall penetration that is typically only a few inches across. You get zoned heating and cooling without a maze of ducts. The U S Department of Energy highlights mini splits as a strong retrofit choice for houses without existing ductwork, for room additions, and for targeted comfort in problem rooms that never seem to feel right in summer or winter. The system delivers both heating and cooling with high efficiency in a compact package that avoids large remodeling work. See the Energy Saver overview for a clear summary of benefits and retrofit details including the small wall opening and line set run options at energy.gov.

Older homes are unique. Many have thick plaster walls, limited attic access, and trim you want to preserve. Mini split equipment keeps most of the work outside or in a single room. The indoor head mounts high on a wall or in a ceiling cassette, leaving floors and windows open. A narrow line cover can be painted to match exterior siding so the retrofit looks tidy on historic facades. Because the system serves specific zones, you condition only the rooms you use which can reduce energy use compared with running a larger central system. ENERGY STAR stresses that certified ductless heat pumps can deliver strong performance in cold climate regions when you choose the right model, and also notes that professional sizing with a Manual J load calculation gives the best outcome for comfort and efficiency. Read more at energystar.gov.

Good use cases include a finished attic or dormer that bakes in summer, a new sunroom or accessory space that would be costly to tie into existing ducts, a garage turned studio, or a back bedroom that never matches the thermostat. For whole home projects, a multi zone system can serve several rooms with one outdoor unit while preserving yard space and limiting exterior equipment.

Single zone or multi zone

Choosing the right layout starts with how you plan to use the space. A single zone mini split pairs one indoor head with one outdoor unit. This is a smart choice when you want to serve a single bedroom, a home office, a studio, or a small addition. The installation is straightforward with a short line set and a simple control setup. Upfront cost is usually lower. Maintenance is easy because there is only one indoor head to clean and service.

A multi zone configuration uses one outdoor unit connected to two or more indoor heads. It is a popular choice for older homes that need comfort in multiple rooms without running ducts through the structure. The outdoor footprint stays small which helps on tight lots. Each indoor head runs independently so you can set different temperatures in different rooms. This can deliver energy savings when parts of the home sit unused during the day. One outdoor unit can also simplify service. You will still want regular cleaning of each indoor filter and coil to maintain performance.

Budget planning matters. Consumer price guides report that a typical installed single zone mini split can fall in a range that begins around the lower thousands of dollars and can extend into the mid range depending on equipment, line set length, electrical work, and local labor. Multi zone projects often start in the mid range and can climb into five figures when you add zones or use high capacity or cold climate models. See current consumer ranges at HomeGuide and broad market context at EnergySage. Real projects vary. Older homes can carry additional costs for electrical upgrades, line hide work, or structural blocking for mounting. A Manual J and an on site visit will produce a more precise proposal than any online calculator. ENERGY STAR explains the value of Manual J and certified models at energystar.gov.

As a general rule, choose a single zone unit for one room that runs hotter or colder than the rest of the house or for a new addition that sits away from existing equipment. Choose a multi zone system when several rooms need comfort and when you want one outdoor compressor to keep the yard clean. If you already own a central system that serves most rooms, it may still make sense to add a single zone mini split for a tough space like a third floor or sun porch while leaving the rest of the home on the existing equipment.

Sizing with Manual J and BTU basics

Proper sizing decides how well a mini split will heat and cool an older home. Sizing too large can cause short cycling which leads to temperature swings, wasted energy, and unnecessary wear. Sizing too small can leave rooms uncomfortable on the hottest or coldest days. The industry standard method for sizing is a Manual J load calculation that considers square footage, window area and type, insulation levels, air leakage, ceiling height, orientation, and local weather data. ENERGY STAR recommends a Manual J for ductless systems to achieve the right capacity for each zone. Learn more at energystar.gov.

Homeowners often ask for a quick way to think about size before a technician visits. A rough square footage to BTU guide can help you start the conversation. Carrier provides general context for capacity selection and reminds buyers that these numbers are estimates. The best practice is to treat this table as a starting point, then rely on a Manual J for the final choice. Carrier placement and selection guidance is available at carrier.com.

| Room or zone size | Typical BTU range | Notes |

|---|---|---|

| Small room such as office or nursery | Six thousand to nine thousand | Higher ceilings, sun exposure, or poor insulation may push higher |

| Medium room such as bedroom or den | Nine thousand to twelve thousand | Corner rooms or large window walls may need more capacity |

| Large family room or open plan area | Twelve thousand to eighteen thousand | Sunrooms and high volume spaces often need a larger unit |

Older homes vary widely. A plaster and brick house with original single pane windows may need more capacity for the same floor area than a similar size room in a house with modern air sealing and insulation. Part of a good assessment looks at envelope improvements that reduce the load so you can install a smaller and more efficient unit. For a helpful primer on insulation, air sealing, and ENERGY STAR choices that support lower energy use, see our guide to green HVAC best practices.

Smart placement for indoor and outdoor units

A mini split works best when air can move freely. Mount the indoor head high on an interior wall so cool or warm air washes the room without obstruction. Carrier suggests placing the unit about six to eight feet above the floor with a few inches of clearance from the ceiling for proper intake and discharge. Keep the front of the unit clear so air can reach the whole room. Avoid mounting above a stove, near strong steam sources, or where direct sun hits the unit for long periods. Do not hide the head behind tall shelves or drapery. When you want a more discreet look, a ceiling cassette or floor console may fit the room better. Placement guidance from Carrier is available at carrier.com.

For the outdoor unit, choose a level surface with good airflow. A small pad, wall bracket, or stand above snow line in colder regions can work. Keep shrubs and debris away from the coil. Leave clearance on all sides for service access and airflow. Think about sound as well. Position the unit where it will not point directly at a bedroom window or neighbor yard if possible. Confirm local codes and permitting needs before work starts. The Energy Saver page at energy.gov covers retrofit friendly installation features that help on older houses such as small penetrations and flexible line routes.

The connection between indoor and outdoor equipment uses a line set that carries refrigerant along with a control cable and a small condensate drain. A single neat wall opening often handles the bundle. The opening can be as small as a few inches across. A line cover matched to the siding keeps the exterior tidy. Manufacturers publish maximum line set lengths and vertical separation limits for each model. Many brands allow runs from roughly fifty feet up to one hundred feet or more depending on model and line size. Always follow the specification sheet for the exact unit. A summary of line set length considerations by brand is compiled by PickHVAC at pickhvac.com.

Every indoor unit needs to drain condensate during cooling. When a gravity drain is possible, the installer routes a small tube to a safe discharge point outdoors or to a proper drain connection. If gravity is not possible, such as for some basement or interior wall locations, a compact condensate pump moves water to a drain. These pumps are small and quiet with ratings for flow and lift height. You can review a typical mini split condensate pump example at Little Giant to see what these devices look like and how they mount near the indoor unit at littlegiant.com. For a homeowner friendly explanation of when a pump is needed, see this overview.

Electrical and structural checklist

Many mini splits require a dedicated electrical circuit. Smaller single zone models may run on a common household voltage while larger or multi zone systems typically call for 208 to 230 volts. The correct breaker size and wire gauge depend on the model and the length of the run. A licensed electrician should review your existing panel and available spaces, then size the circuit in line with the equipment nameplate. Older homes with original fuse boxes or smaller breaker panels sometimes need a service upgrade before the new circuit can be added. A current market overview for panel replacement cost ranges can be found at The Spruce at thespruce.com. Wiring size recommendations by common mini split capacities are summarized by the manufacturer MRCOOL and by PickHVAC, which gives a helpful sense of typical breaker and wire choices. Review those references at support.mrcool.com and pickhvac.com.

Think through structural support for mounting. The indoor head weighs far less than a traditional air handler, yet it still needs solid backing. On plaster walls or in rooms with irregular stud layouts, we may add blocking to prevent vibration and to provide a lasting anchor. For outdoor units, a stable pad or wall brackets keep the cabinet level year round. In snow country, a raised stand protects the coil and speeds winter drainage. For sound control, rubber isolation feet or pads help. Talk with your installer about the best location based on your home construction, lot layout, and where you spend time both indoors and out.

Permits and local inspections often apply to both electrical and mechanical work. Your contractor should coordinate permit submittals and scheduling, then walk you through any inspection findings. In older neighborhoods, historical review may apply to exterior changes on street facing walls. A tasteful line cover, thoughtful placement, and paint matching usually meet those requirements. If questions remain, we can propose routing that keeps most of the visible work in less prominent areas of the property.

Costs, incentives, and accurate quotes

Homeowners want honest ranges for planning. As of the current market cycle, consumer sources report a typical single zone mini split installation can start in the lower thousands and reach six thousand dollars or more depending on capacity, accessories, electrical work, and the difficulty of the line set run. Multi zone projects commonly start around the low to mid thousands and can reach into the teens when several indoor heads, long line sets, and cold climate equipment are included. See the current HomeGuide breakdown at homeguide.com and EnergySage for broad context at energysage.com. Actual pricing is local. The best step is to request three itemized bids that spell out equipment model numbers, capacities, accessories, electrical work, line hide work, permit fees, and a maintenance plan for year one.

Rebates and credits can improve the payback. ENERGY STAR maintains a directory of certified ductless heat pumps plus links to incentives and tax credits where available. This can include federal credits for qualifying air source heat pumps and state or utility programs for high efficiency equipment. Start at energystar.gov. We also cover how incentives interact with other upgrades such as smart controls and insulation in our post on energy saving HVAC upgrades. A quick call with our team can confirm which programs apply to your home and what documentation is needed for submission.

When you review quotes, look for a Manual J summary and a room by room capacity plan. Ask how line sets will be routed and how condensate will drain. Confirm that the electrical work is included or quoted separately. Request warranty details for the equipment and for labor. Clarify what is covered in the first year maintenance visit. A careful scope reduces surprises after install day.

Maintenance and simple ownership tips

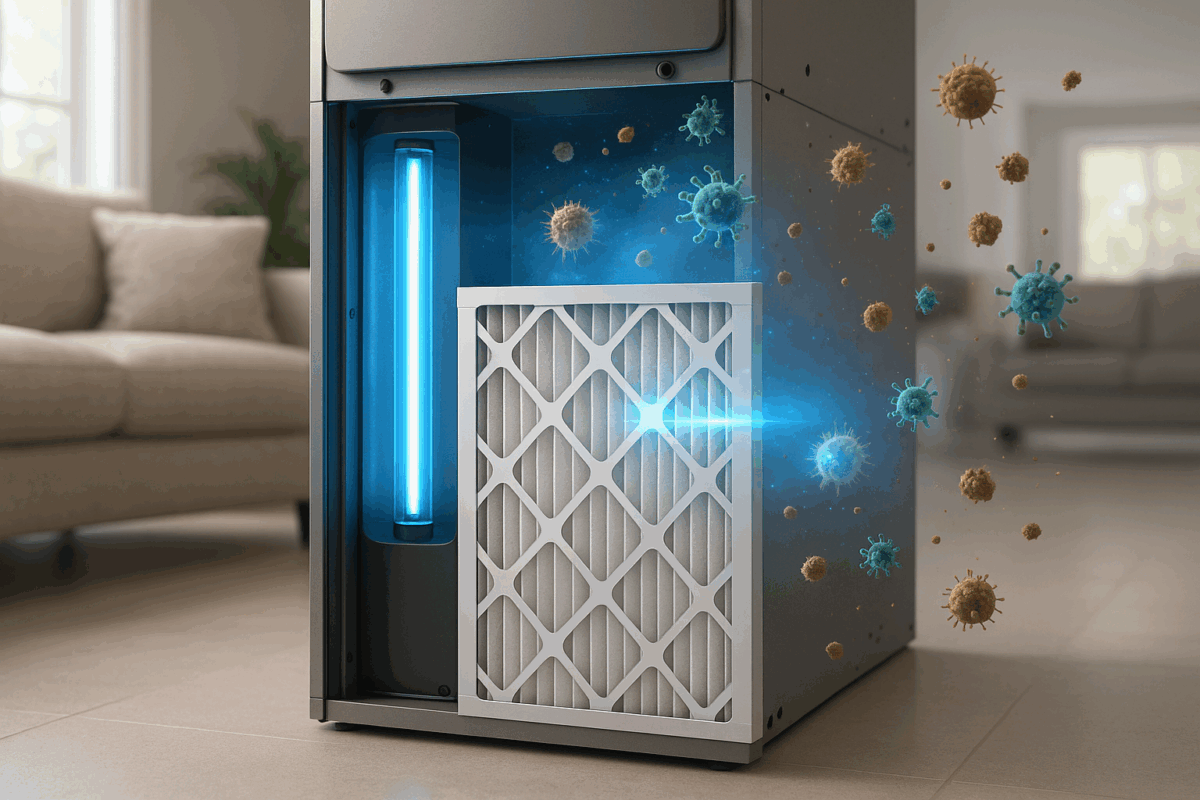

Mini splits are reliable when kept clean. Filters inside each indoor head need regular attention because the coil is compact and the fan moves a lot of air for its size. A monthly check is a good habit during peak seasons. Wash or replace the filters per the manufacturer guidance. Keep the face of the indoor unit clean and free of dust. Inspect the outdoor coil and clear leaves or lint that could block airflow. Verify that the condensate drain is flowing in cooling season. Schedule professional service once a year or twice a year for homes with heavy use, pets, or construction dust. A routine visit typically includes coil cleaning, electrical checks, drain cleaning, refrigerant checks, and a control test. Typical service pricing falls into a modest range for a single system, with added cost for multi zone setups. For a seasonal checklist and tune up details, see our pre season tune up tips.

With proper care, a mini split can deliver a service life in the mid to high teens. Some units run longer when coils stay clean, drains stay clear, and voltage is stable. A maintenance plan can spread out the cost and keep reminders on schedule. We offer installation clients a first year service that includes filter refresh and coil inspection, then a discounted plan for ongoing care. Ask for details during your estimate visit.

Quick decision guide and FAQs

Is a mini split right for a 1920s bungalow with radiator heat and no ducts. Very often yes. A single zone unit can solve a hot bedroom on the second floor. A multi zone system can add cooling and shoulder season heating to the main living areas without touching the historic radiators. The small wall opening and discreet line cover maintain the character of the house while giving modern comfort. The Energy Saver resource explains why this retrofit is so friendly to older construction at energy.gov.

Will a mini split heat well in a cold climate. Many modern ductless heat pumps maintain strong output at low outdoor temperatures. Look for models listed as cold climate by ENERGY STAR and check the heating capacity table at your design temperature. A Manual J that uses local weather data keeps expectations realistic in winter. See the ENERGY STAR guidance on certified ductless heat pumps at energystar.gov.

What about the look of the indoor head. Wall mounted heads are slim with clean lines. In rooms where a wall head feels out of place, a ceiling cassette or a floor console can blend better with the architecture. Line covers outside can be painted to match trim. On many older homes, careful placement makes the installation nearly invisible from the street.

How long can the line set be. Manufacturers publish limits for each model. Many allow runs that approach fifty to one hundred feet with guidelines for vertical rise and additional refrigerant for longer runs. Exceeding those limits can hurt performance. Your installer will measure the planned path and select a model that supports it. See a summary of brand limits at pickhvac.com.

Do I need a new electrical panel. Sometimes. Many single zone units that run on common household voltage can fit on an available breaker. Larger and multi zone systems often require 208 to 230 volts and a dedicated breaker. If your panel is old, full, or uses fuses, an electrician should evaluate it. Replacement cost ranges are linked above from The Spruce at thespruce.com. For typical breaker and wire size guidance by model capacity, see MRCOOL and PickHVAC at the links above.

What if gravity drainage for condensate is not possible. A small condensate pump can be installed near the indoor head to move water to a suitable drain. These pumps are quiet and reliable when installed correctly. Little Giant provides a helpful overview of pump choices at littlegiant.com.

Can a mini split work with my current central system. Yes. Many owners keep the existing central system for most rooms then add a single zone mini split for a home office, third floor, or addition. This targeted approach gives comfort where it is needed while avoiding duct extensions that may be impractical or costly. Energy use can drop because you do not need to run the central system as often for that one problem room.

How do I get an accurate quote. Start with a site visit that includes a Manual J, a room by room plan, and a discussion of placement, line routes, and electrical needs. Ask for an itemized proposal. Request model numbers and performance data. Confirm rebate eligibility for the selected equipment. Our team offers a free in home assessment with a Manual J and a written estimate. You can also study related topics on our blog before we meet.

Your next step

If your older home needs comfort without new ducts, a ductless mini split offers a clean path forward. Start with a qualified assessment that respects the character of your house, confirms the load with a Manual J, and selects certified equipment that fits your rooms and your climate. Ask about current incentives. Plan for maintenance at the time of purchase. The result is year round comfort with smart energy use and minimal disruption to finishes.

Book a free Manual J and in home estimate to compare options, confirm sizing, and see how a retrofit can work in your specific rooms. We can outline costs, available rebates, and a maintenance plan that keeps your new system running clean from day one.

Sources for further reading

U S Department of Energy Energy Saver overview of ductless systems:

energy.gov

ENERGY STAR guidance for ductless heat pumps and Manual J:

energystar.gov

Typical installed cost ranges and zone pricing context:

HomeGuide,

EnergySage

Placement heights and clearances:

Carrier

Electrical circuit and wiring references:

PickHVAC,

MRCOOL

Condensate pump overview:

Little Giant