A2L Refrigerant Safety for the R410A Phase Down

Thinking about replacing your AC or heat pump soon. You are hearing a lot of new terms. A2L. R 32. R 454B. R 410A phase down. This guide breaks down what is changing in 2025. How A2L refrigerants work in homes. What codes require in Austin and across the U.S. How much you might pay. How to pick a system that will serve you for years without headaches.

If you want a quick primer on greener refrigerants and why they matter, take a look at our post on eco friendly HVAC tech. The shift is real. The goal is lower climate impact without giving up comfort or safety.

The 2025 refrigerant change

Starting January 1, 2025, new central AC and heat pump models for homes must use refrigerants with a global warming potential of 700 or less. This comes from the EPA Technology Transitions program. It effectively ends new products that use R 410A for residential comfort cooling after that date. The EPA also limits the sale of higher GWP products three years after the compliance date for each sector. You can review the sector table on the EPA site for details on the limit and date framework at epa.gov.

The EPA provided a limited path for field assembled split systems that were already in the pipeline. Components that were manufactured or imported before January 1, 2025 can be installed through January 1, 2026. After that date, a new field assembled system must use a refrigerant at or below the 700 GWP threshold. This sell through provision is described in the interim action notice at epa.gov.

The broader phasedown of HFCs sits under the AIM Act. Supply steps down in stages through 2029 to 2036. The EPA FAQ page shows the step schedule from 2024 onward. This matters for price and availability. Reduced supply can add pressure on cost for older refrigerants. The schedule is posted at epa.gov.

Key dates for homeowners

- Jan 1, 2025. New residential AC and heat pump products must use a refrigerant at or below 700 GWP.

- Jan 1, 2026. Last day to install split system components made before 2025 that use higher GWP refrigerants.

- Supply steps down again in 2029. Long term supply settles at a small fraction by 2036 under the AIM Act.

Recent legal action also supports the direction of travel. In August 2025 the D.C. Circuit upheld the EPA rule that allocates HFC allowances. That ruling helps stabilize the phasedown plans. Read the coverage at Reuters.

Why the industry is moving to A2Ls

A2L refrigerants give a large cut in climate impact compared to R 410A. R 410A has a GWP near 2088. R 32 is about 675. R 454B is near 466. Both R 32 and R 454B sit in the A2L safety class. That class means lower toxicity with a low burning velocity. Systems that use these refrigerants can hit strong efficiency targets. Your comfort does not have to suffer. Your bills can improve.

Want a quick look at how greener refrigerants fit into a cleaner home plan. See our tips for green HVAC practices. Refrigerant choice is one piece. Duct sealing, filtration, and controls matter too.

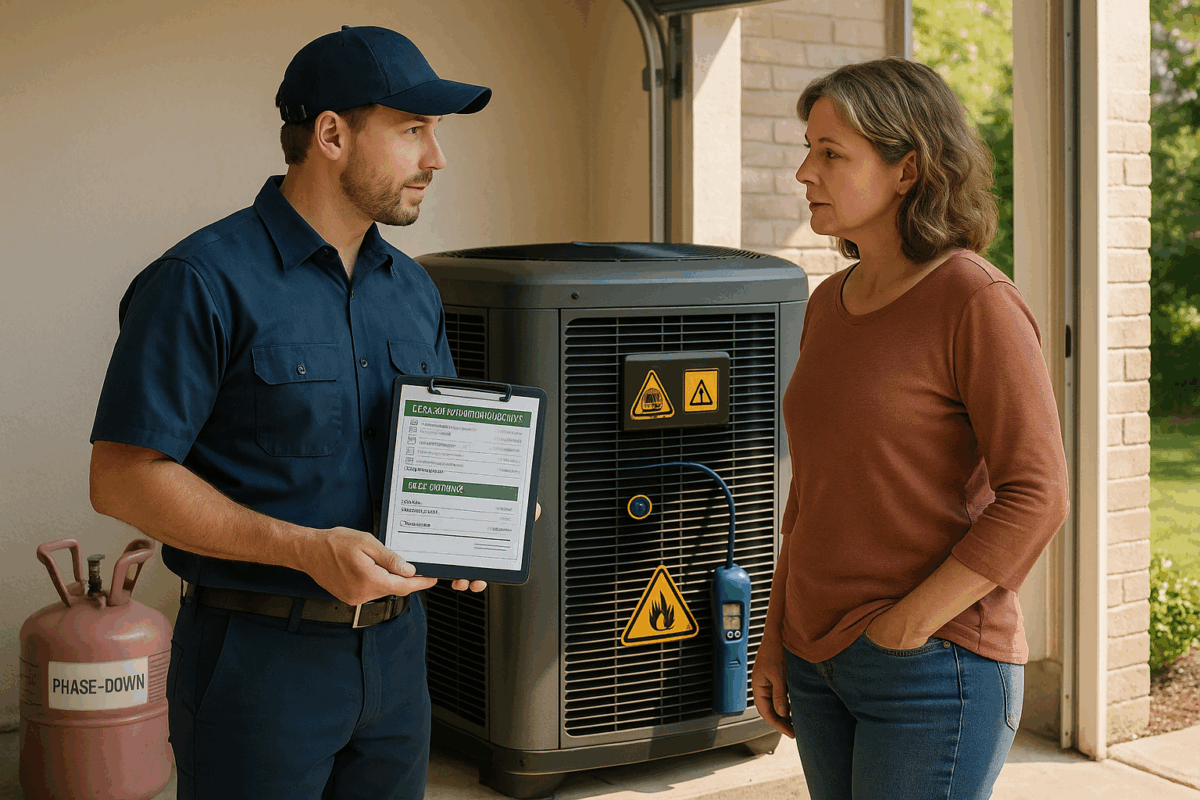

Are A2L systems safe

Short answer. Yes, when installed to code by trained contractors using listed equipment. A2L means lower toxicity with a flammability subclass that has low burning velocity. This is defined by ASHRAE Standard 34. The A family includes A1, A2L, A2, and A3. A1 is non flammable under test conditions. A2L is labeled mildly flammable because it can burn if a very specific mix and an ignition source are present. You can read the classification context in the ASHRAE Handbook at ASHRAE.

What mildly flammable means

A2L refrigerants need a relatively rich concentration in air before they can ignite. That threshold is called the lower flammability limit. R 32 has an LFL around 14.4 percent by volume. R 454B has an LFL around 11.8 percent. You also need a strong enough ignition source. Normal operation of listed equipment does not create that mix or condition. Industry training resources help frame that context for technicians and homeowners. See definitions in this ACHR News explainer at achrnews.com.

Model codes treat A2L equipment as suitable for homes with specific safeguards. These safeguards are baked into the product listing and the installation rules. The goal is prevention, early detection, and mitigation.

Built in protections

The current safety baseline for comfort cooling equipment is UL 60335 2 40. This standard requires design limits for refrigerant charge based on room size and layout. It also calls for integral refrigerant detection and mitigation for certain systems and sizes. Sensors must react at or below 25 percent of the lower flammability limit. That is a built in safety margin. Detection triggers controls that move air or shut down the system to dilute or prevent a hazard. Setpoints are part of the listing. They are not field adjustable. UL explains these updates in detail at UL Solutions.

Think of this as layered protection. The equipment must meet charge limits. Some systems include integrated detection due to their amount of refrigerant or the space they serve. Sensors must trip early. The system must respond in a predictable way. Contractors install per code to protect every space. Your job is simple. Hire trained pros who follow the rules. Replace filters and schedule yearly service.

If you want to keep your system clean and safe all season, bookmark our pre season tune up tips. Small steps prevent bigger problems.

Codes and permits

A2L equipment is permitted by the 2024 International Mechanical Code for comfort cooling with references to updated UL standards for high probability systems. The ICC Building Safety Journal covered the A2L changes for the 2024 cycle at iccsafe.org. Even with model code support, local adoption can vary during a transition year. Some states and cities have already adopted new codes. Others may be on a prior edition for a period.

Model code provisions and Austin

Austin adopted the 2024 technical building codes with an effective date of July 10, 2025. That timing gives clarity for A2L enabled installs in our market. The City announcement is posted at austintexas.gov. If your project is outside Austin city limits, your jurisdiction may be on a different adoption path. Permits and inspections will follow your authority having jurisdiction.

For a national view of which states and cities allow A2L refrigerants today, AHRI maintains a status map. It is a handy check during planning at ahrinet.org.

How to check your AHJ

Call your city or county permit office. Ask which code editions they enforce for mechanical work. Ask whether A2L refrigerants are permitted for residential comfort cooling. Ask about any local amendments that add clearances or equipment requirements. Your contractor should also confirm and pull the permit for you.

Smart controls can help meet comfort goals while you work within local rules. See ways to set up smarter savings in our guide to smart HVAC upgrades.

R 32 vs R 454B

Two low GWP choices dominate new unitary equipment. R 32 and R 454B. Both are A2L refrigerants. Both meet the EPA rule for 2025. Each has brand support and product depth. Both can deliver strong performance when paired with the right coil, compressor, and controls.

GWP, efficiency, and adoption

R 32 has a GWP near 675. Some brands in the Daikin group, including Goodman, favor R 32 in many product families. Goodman maintains a homeowner resource hub at goodmanmfg.com. R 454B has a GWP near 466. Carrier markets it as Puron Advance and adds integrated dissipation features to its new lines. Read more at carrier.com. Trane and American Standard are also moving to R 454B with integrated detection and mitigation strategies. See Trane homeowner guidance at trane.com.

There is no single winner for every home. Lab numbers on GWP do not predict your comfort or your bill. The system design does. Size it right. Match indoor and outdoor components. Use quality installation practices. Verify code compliance. That gives you safe cooling with lower impact.

What matters more than GWP alone

Whole system efficiency should lead your decision. A better matched system can cut energy use. Look at rated efficiency, compressor type, blower control, and coil design. Consider noise levels. Consider warranty terms and local service support. Factor in rebates from your utility or state program. Ask your contractor for a load calculation and a duct review. That beats picking a refrigerant label in isolation.

If you want a broader view of future ready features, our post on AI in home comfort shows how better controls drive savings today.

Keep or replace your R 410A system

You can keep using and repairing an existing R 410A system. The EPA allows manufacture of components for servicing after January 1, 2025 when labeled for servicing existing equipment only. If you replace both the outdoor unit and the indoor coil after January 1, 2026, that counts as a new system. A new system must use a refrigerant at or below 700 GWP. The EPA FAQ explains these service rules and definitions at epa.gov.

Service or full replacement

If your R 410A system has life left, parts and refrigerant will remain available, subject to phasedown supply. Repairs can extend its useful life. If the compressor fails or the coil leaks and the system is old, a full replacement may make more sense. From 2026 forward, a full field assembled replacement must be low GWP.

No drop in swaps and no mixing

R 454B does not drop in to an R 410A system. R 32 does not either. There are no known low GWP A1 drop ins for typical unitary systems. Never mix refrigerants. Follow the manufacturer instructions and use matched components. Johnson Controls provides a clear overview of these rules at johnsoncontrols.com.

Line sets matter too. Your installer will confirm if a line set can be reused after proper cleaning or if replacement is required. Correct brazing, nitrogen purging, evacuation, and charge procedures protect the new system and the leak detection architecture. Good practice is worth it. If you want routine care steps that protect your air and equipment, see our post on preventing mold in HVAC.

What it will cost

Expect some increase in upfront price for new low GWP models. OEMs guided roughly ten percent or more during 2024 to 2025 for certain lines. Inflation and supply chain shifts also play a role. This change introduces new components, detection hardware in some cases, plus new tools and training for contractors. ACHR News covered this trend at achrnews.com.

Plan your project to find savings beyond the sticker. Right sizing prevents short cycling. Duct fixes cut losses. Smart controls trim runtime without sacrificing comfort. Seasonal rebates and federal credits may offset a portion of the cost. Get quotes from reputable contractors who have completed A2L training. Compare full scope proposals. Look beyond the tonnage line.

If you want ideas that pay back quickly, our guide to smart HVAC upgrades highlights add ons that save energy. Our green HVAC practices article lists simple habits that cut waste too.

Future proof your purchase

Ask better questions before you sign. You can get a safe, quiet, efficient system that meets the new rules. You can also set it up for smooth service throughout its life. Use this homeowner checklist during sales calls and at the walkthrough.

A2L ready checklist

- Confirm the equipment is listed to UL 60335 2 40. Ask for the model number and the listing class.

- Ask whether your system size and layout require an integral refrigerant detection system. If the answer is yes, confirm the sensors and controls are the exact parts specified by the OEM. No field changes to setpoints.

- Make sure your installer has completed A2L refrigerant safety training. ACCA offers a recognized program at acca.org.

- Verify matched components. Outdoor unit, indoor coil, and controls must be designed to work together. No mixing of refrigerants or parts.

- Discuss line set procedures. Cleaning, pressure testing, and evacuation must follow the OEM manual.

- Check local code status and permit requirements. AHRI maintains a map that shows jurisdictions authorizing A2Ls at ahrinet.org.

- Compare brand roadmaps. Carrier focuses on R 454B with added safety features at carrier.com. Goodman highlights R 32 education at goodmanmfg.com. Trane is rolling out R 454B across lines at trane.com.

A small note for those who like to peek behind the scenes. Cylinder markings are changing. AHRI Guideline N updated container IDs. Flammable refrigerants receive a red band near the top. Labels remain the primary ID. This helps techs pull the right cylinder for the right job. Read about the update at ahrinet.org.

Rebates, smart controls, and maintenance

Rebates can change monthly. Ask for a rebate check during your estimate. Utilities, state programs, and federal credits can all lower the cost. Smart controls trim energy use during peak hours. They also help the system reach the setpoint without stress. See how smarter controls pay back in our smart upgrades guide.

Maintenance helps protect an A2L system for the long run. Clean coils. Correct airflow. Tight electrical. Proper charge. Those basics extend life. Read our pre season tune up tips to get ahead of summer heat. Keep indoor air dry and clean to reduce strain. Our mold prevention guide shows simple steps that help.

If you want a quick read on why the refrigerant shift supports a cleaner home, start with greener refrigerants. That page connects the dots between refrigerants, efficiency, and comfort.

What this means for Austin homeowners

Austin is moving to the 2024 codes with an effective date in July 2025. That clears the way for A2L systems in most homes when permitted and inspected. Many brands now ship A2L models sized for Austin homes. Availability improves month by month. Pricing trends reflect the new tech and training. Expect quotes that look a bit higher than last year. Expect better options for efficiency.

We work with leading manufacturers that have published A2L safety architectures and training. We follow UL 60335 2 40. We verify charge limits by room size. We install listed leak detection when required. We use OEM specified sensors and controls. We train our team through programs like the ACCA A2L course. That is how we deliver safe, quiet comfort with lower climate impact.

Considering an HVAC replacement in Austin. Schedule a consult with our team. We will review A2L ready options, available rebates, and a code compliant plan for your home.

FAQ

Can I still buy an R 410A AC in 2025

Only in limited cases. The EPA allows installation of higher GWP split system components that were made or imported before January 1, 2025 through January 1, 2026. After that date, a new field assembled system must use a refrigerant with a GWP of 700 or less. Parts to service existing R 410A systems remain available.

Do A2L systems need leak detectors inside my home

Sometimes. It depends on the system charge, the space volume, and the specific equipment. UL 60335 2 40 requires an integral refrigerant detection system for certain sizes and layouts. Many new units include built in sensors and controls for this reason.

Which is better, R 32 or R 454B

Both meet the EPA rule. Both are A2L. Performance depends on the specific model, coil match, and installation. Focus on whole system efficiency, code compliance, and installer expertise. A good design beats a label choice.

Will my old R 410A system become illegal

No. You can use and repair an existing R 410A system through its useful life. Service components remain available. A full new system installed after January 1, 2026 must use a low GWP refrigerant.

Should I replace my line set

Your installer will advise. Some line sets can be cleaned and reused. Others should be replaced to protect the new system. Follow the OEM manual for cleaning, pressure testing, and evacuation. Proper line set work is a key part of A2L safety.