HVAC Air Duct Materials Guide Pros Cons Best Uses

Choosing the right material for your HVAC air ducts sets the foundation for reliable indoor comfort, energy efficiency, and indoor air quality. Many homeowners wonder how duct material impacts the performance and longevity of their system. This article provides deep insights into the most common HVAC duct materials used today. With an emphasis on strengths, weaknesses, and the conditions that make each option suitable, this guide aims to help those upgrading, replacing, or planning new ductwork systems. Whether you manage a home, apartment building, or business, understanding air duct types makes a real difference in long-term results.

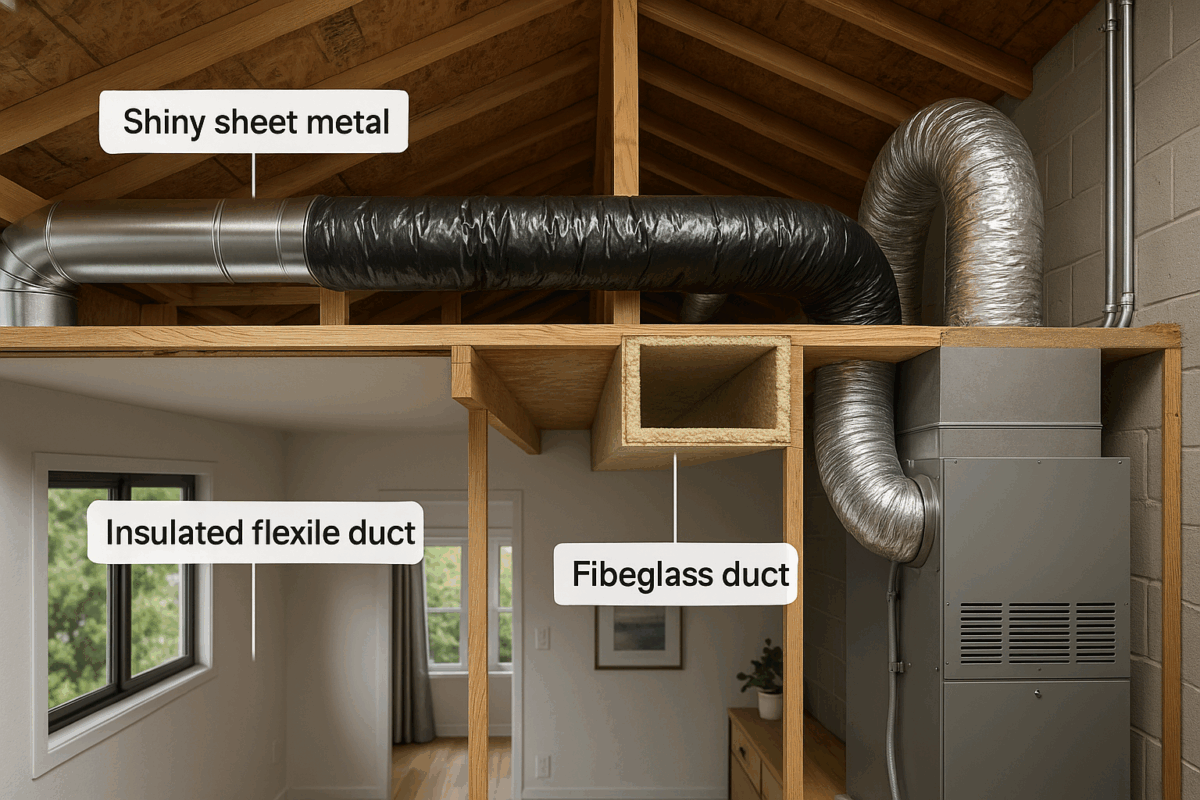

Understanding HVAC Duct Materials

HVAC duct materials influence much more than just airflow. Each air duct type affects everything from sound level and energy bills to the risk of mold and the air you breathe. Material selection impacts how easily ducts can be installed, how often they need maintenance, and how well the system resists physical stress and environmental hazards. Popular air duct materials each bring unique properties. Some shine when durability is a priority while others offer cost savings or insulation benefits. Walking through every major air duct type, weighing their best uses, reveals how to make informed choices that meet your needs. Reviewing these options will help you identify what works best for your property and climate.

Galvanized Steel Ducts: Strength and Fire Resistance

Galvanized steel stands as one of the most widely used materials for commercial and residential HVAC ducts. The steel core receives a zinc coating in a specialized process, which helps the duct resist corrosion even in moist or humid air. This material’s real strengths shine in environments where physical toughness and longevity matter most.

Galvanized steel ducts handle bumps and impacts, making them a favored choice for high-traffic or industrial sites. Their fire resistance provides safety during emergencies. The smooth inner surface creates less drag on moving air, supporting quiet and efficient system operation. Over time, this trait lowers the risk of mold development and minimizes debris build-up. While installation is more labor-intensive due to the weight of each segment, the payoff comes in a long service life punctuated by few issues.

Cost remains a consideration, as galvanized steel stands at the higher end of the material spectrum. The added expense reflects years of dependable use. For homeowners or businesses seeking peace of mind regarding fire protection and lifespan, galvanized steel ducts fit the bill. Both new builds and renovations benefit from their unwavering reliability in demanding conditions.

Aluminum Ductwork: Lightweight and Rustproof

Aluminum appeals to those seeking equipment that is quick to manage yet stands up to challenging environmental conditions. This material checks boxes for ease of handling, which cuts installation time and makes it ideal for complicated layouts. It naturally resists corrosion, making it perfect in coastal areas or spaces where humidity might otherwise shorten the lifespan of metal ducts.

Flexibility adds to its appeal. Installers find it easier to fit aluminum ducts around tight corners or unusual architectural features. Aluminum’s light nature means the supporting structures do not need the same heavy-duty bracing required by galvanized steel. While the cost trends higher compared to other options, many find the balance of longevity and ease of use worthwhile.

One reality with aluminum involves its softness as a metal. It can pick up dents or scratches from heavy impacts. For homes in wet regions, aluminum ductwork offers a great solution to rust worries. With professional maintenance, these ducts keep performing quietly and cleanly for many years. Aluminum also helps in remodels or expansions where the original space was not designed with ductwork in mind, allowing for creative solutions without sacrificing quality.

Fiberglass-Lined Ducts: Sound Dampening and Insulation

Where sound control and thermal stability matter, fiberglass-lined ducts have proven their value. Their core is typically a metal, most commonly sheet metal, which receives a lining or wrap of fiberglass insulation. This two-layer construction serves both to dampen noise from air handling equipment and to prevent unwanted heat exchange.

The ability to reduce the sound of passing air appeals in offices, hotels, schools, or any building where quiet matters. These ducts keep heated or cooled air at the right temperature as it travels, improving energy usage. However, there are special cleaning and maintenance considerations. When the internal fiberglass starts to degrade, small particles could enter the air supply. Moisture that becomes trapped could trigger mold growth, particularly after water damage events or if the ducts are not kept clean.

Cautious maintenance is needed. Only specialists with the correct equipment should clean or repair these ducts. Despite these challenges, fiberglass-lined ducts remain popular in spaces where other materials would result in noisier or less efficient operation. Their value grows in large office complexes or entertainment venues where distractions from HVAC sounds are unwelcome.

Fiberboard Ducts: Cost Savings and Simple Insulation

Fiberboard ducts provide an affordable alternative to traditional metal ductwork. These are created by compressing fiberglass strands with resin, resulting in a material that is rigid yet lightweight, and inherently insulated. The insulation is built directly into the duct, reducing the need for extra wrapping or covering.

For projects with tight budgets, fiberboard brings upfront savings. It can be cut on-site to suit various layouts and is easy for installers to move and adjust. The ability to minimize heat loss or unwanted heating of cooled air gives fiberboard strong appeal in mild climates and low-traffic areas.

However, the structure’s porous nature can catch and hold dust, dirt, and moisture. Over time, this increases the risk of mold growth or indoor air quality issues. Fiberboard wears down more quickly than metals, making frequent replacement or repairs more likely in demanding settings. In environments with proper moisture control and where the system will see only moderate use, fiberboard serves as a practical, budget-friendly choice.

Flexible Ductwork: Versatility for Tight Spaces

Flexible ducts, as the name suggests, allow for twisting and turning through challenging underfloor spaces and sharp corners. Built from a wire coil surrounded by plastic and then wrapped in insulation, they quickly adjust to bespoke layouts without the need for special tools or labor. Their lower cost makes flexible ducts suitable for use where budget constraints exist or in areas that will not see rough handling.

However, they are not as tough as rigid materials. Over time, rough installation or physical pressure can leave them torn or sagging. These flaws restrict airflow, drive up energy use, and create opportunities for contamination. Flex duct is highly effective for short runs from a main duct branch to an individual vent. It fills the gap in spots traditional ducts cannot reach, such as ceiling drops or tight attic corners.

Correct installation is essential. Professional attention reduces the risk of kinks that choke air movement. Insulation protects the air inside from temperature swings. Flexible ductwork remains a go-to solution for renovations and additions where working space is extremely limited, as well as for quick fixes where long-term durability is less of a concern.

PVC Ducts: Control Moisture and Chemical Exposure

PVC, or polyvinyl chloride, brings another set of benefits to the HVAC world. Resistant to water and many chemicals, these ducts work in places where high humidity or corrosive vapors would quickly damage metals. PVC duct installations show up in swimming pool buildings, laboratories, and some industrial spaces. Their resistance to corrosion enables systems to last longer in environments with heavy moisture or chemical fumes.

Installation tends to be quick. Components are light and easy to secure together. However, PVC’s main drawback is its limited tolerance of high temperatures. It cannot be used where heated air would build up enough to reach softening or deformation temperatures. For ventilation, cooling, or where only modest heat is expected, PVC air ducts present a fitting solution.

Maintenance for PVC ductwork is straightforward. The nonporous surface sheds water and most chemicals without breaking down. However, operators must avoid using PVC in sections intended to carry hot exhaust or furnace air. Deciding where to use this duct material starts by matching your system’s demands to the strengths of PVC, always considering both safety and comfort needs.

Fabric Ducts: Flexible, Quiet, and Visually Appealing

Fabric ducts, sometimes called textile ducts, offer a unique approach compared to rigid metal or plastic alternatives. Made from textiles, they distribute air by way of porous fabric, creating a gentle, even flow. This can help eliminate hot and cold spots and minimize drafts. Their lightweight nature means quick installation and easy adjustment for seasonal or evolving needs.

One advantage lies in appearance. Color options and flexible layouts make them suitable for architectural projects or venues with strict design requirements. Maintenance differs from rigid ducts, as fabric segments often need regular removal and washing to prevent mold or mildew. They may not last as long as metal ducts under wear or daily physical stress, but their ease of use wins favor in special installations or where aesthetics matter.

Fabric ducts shine in fitness centers, event venues, or retrofits where traditional infrastructure cannot be installed or does not match the room’s style. Management teams enjoy the way these systems handle frequent changes in occupancy or layout, responding to comfort needs with minimal disruption.

Comparing Air Duct Types for Different Needs

Sorting through HVAC duct materials brings up questions of environment, cost, health, and practical fit. In residential settings, galvanized steel or aluminum works well in most climates if long lifespan and fire resistance top the list. Flexible ducts shine in retrofits, short connections, and multi-family properties where traditional access is blocked. Fiberglass-lined options provide quieter performance in office spaces or educational buildings. Fiberboard gives a cost-saving advantage for homes without high moisture concern where budget is a key factor.

Commercial spaces with advanced air quality requirements or changing layouts often turn to fabric ducts, balancing performance with looks. Meanwhile, laboratories, indoor pools, or chemical processing sites benefit from PVC ducts, as resistance to water and chemicals takes center stage. Each type comes with unique maintenance challenges, installation differences, and long-term value claims.

Choosing the right material can be influenced by your region’s climate, your building’s demands, and your future plans. Consult with experienced HVAC professionals to match each material to its intended role. Modern systems can blend multiple duct types in a single layout, optimizing installation labor, safety, and performance throughout the building.

Impact on Air Quality and Energy Use

Every air duct type directly affects health, comfort, and house efficiency. Smooth metal surfaces reduce dust and support easy cleaning. Fiberboard and fiberglass options bring built-in insulation but require routine checks against moisture and contamination. Proper selection reduces energy waste as each material’s insulation and airflow properties limit heating or cooling loss as air travels from the unit to rooms.

Mistakes in duct material selection increase allergy risks, energy costs, and system downtime. Well-chosen ducts maintain steady temperatures, filter pollutants more effectively, and eliminate nuisance noise that can disrupt sleep or work processes. Energy savings often grow over time when ducts have minimal airflow resistance and are protected from outside temperature swings, supporting equipment longevity and lower utility bills.

Indoor air quality remains a constant concern for homeowners and facility managers alike. Metal ducts, especially galvanized or aluminum, remain the baseline for clean airflow. Where insulation is needed, external wrapping prevents fibers from escaping but may carry extra installation steps. Flex ducts require careful handling to avoid accidental tears that create mold points or dust traps. PVC or fabric versions keep air fresh in specific niches where their strengths counter ordinary risks.

Installation and Maintenance Considerations

Although upfront cost and material availability guide many first decisions, installation factors can tip the balance. Galvanized steel ducts demand precise measurement, specialized tools, and skilled installers. Aluminum offers easier handling, fitting complicated frameworks or low-clearance spots. Fiberboard and flexible ducts stand out in timesaving capacity, though installers must work with care to avoid accidental crushing or misalignment.

Ongoing maintenance sets long-term value. Some ducts withstand vacuuming and heavy scrubbing. Others need delicate cleaning to avoid disturbing surfaces or insulation material. Homeowners and building operators should plan on periodic inspections to catch sagging, disconnected joints, moisture intrusion, and early signs of dust buildup.

When selecting air duct types for your next project, factor in both immediate usability and total ownership cost over the entire working life of the system. Maintenance contracts often look very different between duct types and may affect your ability to hold warranty coverage or meet state code requirements. Thoughtful planning now can save significant time and money later, prolonging the life of both ductwork and air conditioning equipment while maintaining confidence in system hygiene.

Key Points for Choosing Ductwork Material

Selecting the right material for HVAC ductwork requires careful assessment of conditions and project goals. Think ahead to anticipated energy demands, occupant health goals, and system access needs. Prioritize durability, especially in high-use or exposed locations where damage would be costly. Consider combined use of materials when conditions vary from one section of the building to another.

In climates with humid air or heavy rainfall, aluminum, PVC, or high-quality galvanized steel keep corrosion at bay. For spaces like theaters or hotels where silence enhances comfort, fiberglass-lined ducts or sound-dampening fabric types perform best. Value-focused goals point toward fiberboard for mild climates, but only when moisture is strictly controlled. Where appearance is a factor, fabric ducts match creative design while providing ease of change over the years.

Rely on professionals to assess connections, airflow balance, and sealing requirements before final installation. Installers need to match material strengths to each job, ensuring vents and returns stay clear, air moves quietly and cleanly, and the system remains flexible enough for future upgrades.

Future Trends in HVAC Duct Materials

Trends in HVAC design push for greater energy efficiency, air quality, and adaptability. Manufacturers continue to refine existing air duct types, adding antimicrobial coatings, stronger joinery, and lighter frames to current favorites. Technologies that allow remote inspections or simpler in-place cleaning promote longer system life and lower maintenance needs.

In many regions, demand for nontoxic, recyclable duct materials grows each year. Aluminum recycling processes now make new installs more environmentally friendly. PVC manufacturers introduce safer formulas for labs and schools. Fabric duct producers continue to expand color palettes and finish options, supporting creative architectural design as well as practical comfort. For the foreseeable future, the range of choices will only broaden, giving property managers and homeowners more power to tailor systems.

Choosing HVAC duct materials is not just a technical task. The right decision creates a strong foundation for system performance, protects health, and supports lower energy consumption year after year. Think ahead to your unique needs with each property and consult with trusted professionals before finalizing your system design. The backbone of any comfortable home or business lies in these unseen channels. Make your choice wisely to enjoy quiet comfort, low bills, and safe, healthy air in every season.